Technical Article

Published 03/2024

How to Improve Power Reliability in Mining Operations

Power reliability matters on mine sites.

Even minutes of outages can cost millions in lost production. Unplanned outages can cause further plant damage, introducing costs to operations where extraction viability relies on plant availability.

Fortunately, there are key considerations that power engineers can make in procurement and network design that provide improvements to power reliability. These guidelines mitigate outage risk and improve mine site safety, reliability and performance.

IP Ratings

First and foremost, the Ingress Protection rating of electrical switchgear is critical for reliability.

Modern pole mounted circuit breakers and reclosers are sealed from the environment, carrying a rating of IP65 and above.

Examples such as NOJA Power’s OSM Recloser carries an IP rating of IP65 for the pole mounted circuit breaker, and a rating of IP66 for the associated controller.

Gone are the days of vents for switchgear controllers. These openings were needed for earlier generation electronics to assist with cooling, but the vents are a gateway for dust, vermin, and moisture.

By removing vermin, dust and moisture ingress as a risk for asset failure, engineers can reduce their outage risk exposure and improve network reliability. There is no need for vents on modern switchgear controllers.

Dead Tank Design

Another key consideration is resilience to atmospheric pollution. Dead tank switchgear design is the act of placing the insulation and interruption system (usually a Vacuum Interrupter), inside a metal enclosure, often referred to as a “tank”.

While Live Tank designs are simpler and cheaper to make, they expose the insulating epoxy to the environment. Dead tank designs shield the insulation from environmental UV radiation.

Another added bonus of dead-tank designs is the provision for Arc Fault venting. Arc fault venting is the controlled release of arc energy directed away from operators in the event of a catastrophic failure. Live tank designs do not have this capability – a catastrophic failure is uncontrolled in those designs, leading to detonation and shrapnel. When presented with a safety option of dead tank vs live tank, and given approximate cost parity, it is difficult to justify a failure to specify arc fault venting.

Modular Controller Design

When specifying equipment for high power uptime environments, a key consideration should be made for spares and serviceability of equipment. Modern recloser controllers, such as NOJA Power’s RC series devices, have discrete modules for user replacement. A module that has suffered lightning impulse damage can be easily replaced by technicians on site. It’s a case of undoing the two or four fasteners, swapping the module, reinserting the cables before the device can be powered up again. Once online, technicians can reload settings and have the device back in service.

Legacy RTU designs or wiring-intensive systems are incomparable with modern switchgear control designs. A modular controller design with readily available spares is essential for reliability.

Auto Changeover Schemes

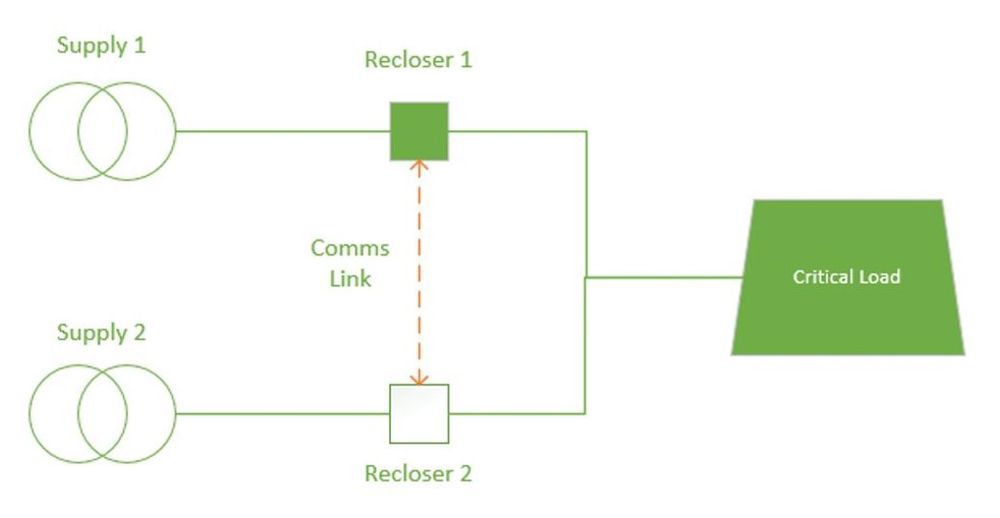

Finally, for mission critical power reliability, engineers can specify the availability of Auto Changeover functionality in their switchgear controls.

This system allows a peer to peer communications link between a primary and backup power supply to a critical load.

Devices such as NOJA Power’s OSM Recloser system ship standard with this capability, where all that is required is a network link between the two switchgear controllers.

This application is so common that a variant of NOJA Power’s Ground Mount Kiosk Switchgear has this entire system in a single assembly.

Known as a 4000 series GMK, these units bring two OSM Reclosers and Controls into a pad mounted platform, allowing improved network uptime from two independent sources.

Conclusion

“Our electricity utility hardened products are also ideal for mining applications and are often installed in mines applications today,” says NOJA Power Group Managing Director Neil O'Sullivan.

Mine site power systems reliability can be improved through specification action at the procurement stage. Considering IP ratings of equipment, dead tank design, modular spares and network auto-changeover techniques are all clear methods for improving asset reliability.

For more information, visit www.nojapower.com.au.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →