Technical Article

Published 08/2019

Distributed Automation VI – Smart Grid Automation IEC61499

As we explored centralised automation in our previous edition, the key modus operandi of the system is for all remote Intelligent Electronic Devices to report their status and readings to a centralised automation system, where the automation/switching decisions are made. Centralised automation is essentially the automation of the SCADA control room’s actions, replacing the operators who act on signals from the field with pre-programmed algorithms.

Ultimately, protection devices in the field will still have some local automation, such as Autoreclosing, but the key theme of centralised automation is to provide specific signals to a central control system to make the correct decisions for re-switching the grid in adverse conditions.

The recurrent issue in rolling out these centralised schemes is the challenge of interoperability:

“Why does x vendor’s signal y work differently to z vendors signal y?”

When all signals that are provided to the centralised automation system should be consistent across brands, the minor esotericisms of each IED can cause headaches for Protection and Control Engineers.

NOJA Power’s solution to this challenge is to build a PLC logic engine standard into the OSM Recloser RC Control System – IEC 61499. Given its flexibility in automating networks, the functionality itself has inherited the designation “Smart Grid Automation (SGA) IEC61499”.

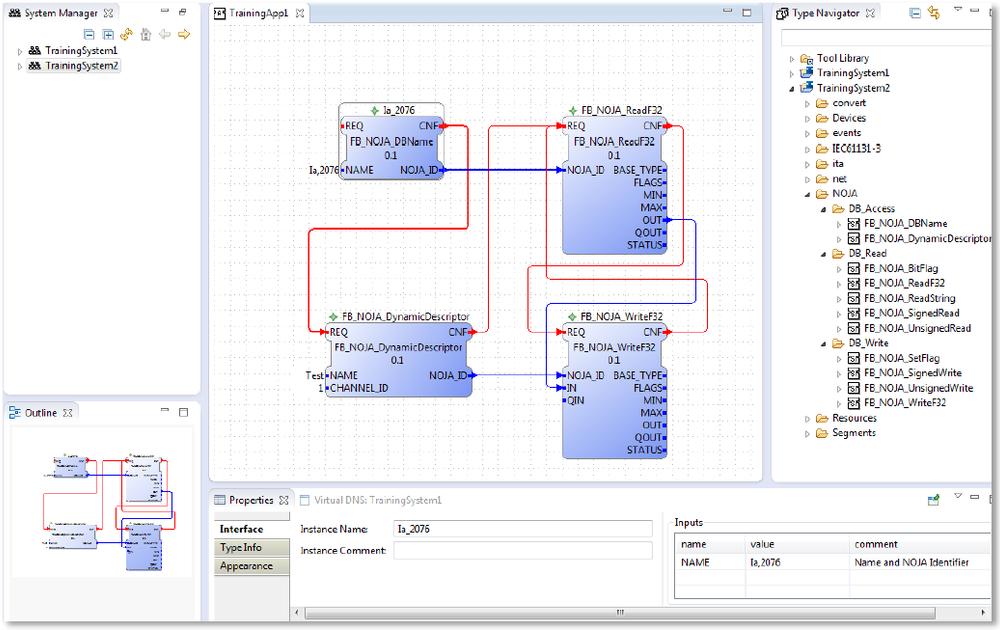

SGA is an event-controlled automation description platform, which uses function blocks to describe automation behaviour. Users can build their own applications in SGA, install them into a NOJA Power OSM Recloser to create new functionality. SGA has access to all signals and status in the NOJA Power Recloser, providing control engineers with the capability to edit, redesign or tweak functionality to suit the local automation requirements.

For Centralised automation schemes, this capability provides tremendous flexibility in implementing signals that leave the OSM Recloser destined for the utility control room. It also provides legacy compatibility, as signals can be edited to appear the same as other network legacy equipment, shedding the shackles of enslavement to the incumbent asset base of incompatible equipment.

SGA does not have to be confined to combining and permutating signals for the purposes of automation – it could be used to develop automation algorithms itself.

Using IP communications, SGA Algorithms can be designed to publish and subscribe to information and event flow between devices compatible with the IEC 61499 standard, whether it is a series of NOJA Power OSM Reclosers, or a mix of connected PLC and Recloser devices.

Field examples of this functionality that we have witnessed thus far include:

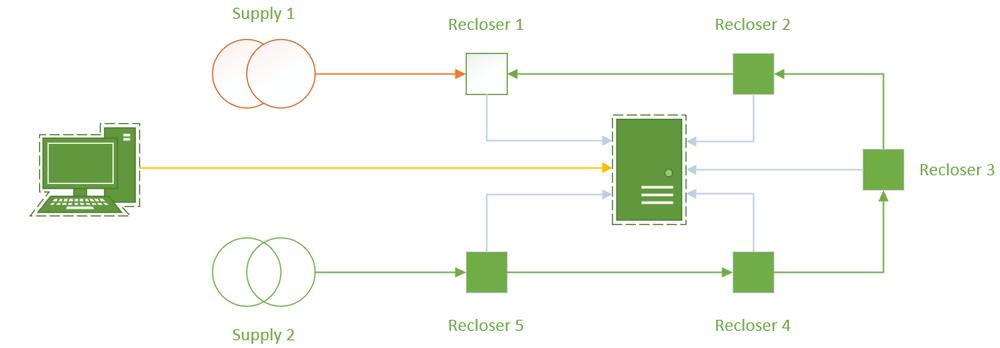

- Implementing specialised Auto-Changeover Schemes between two reclosers, using a variation of controls to define the response of the algorithm beyond the standard ACO capability in the device.

- Implementing a Ring-Mode automation scheme, (as covered in Automation IV), but with Peer to Peer communications between the tie-point recloser and midline reclosers preventing the extra close-onto-fault in system abnormal.

- Implementing the linking of settings change between a series of devices – i.e., if Earth Fault protection is turned on at the substation, all reclosers down the feeder also have Earth Fault enabled, mitigating the risk of operator error in the repetitive task of turning on settings in multiple devices.

“IEC61499 really puts the automation power into our utility customer engineers’ hands,” reports NOJA Power Group Managing Director Neil O’Sullivan. ”Rather than requiring manufacturers to hard code new functionality, our customers have the power and ability to create their own functionality and get the most out of the automation systems.”

This week, our focus on IEC61499 provides the guidelines for achieving automation where legacy systems burden is great, or for versatility in implementation of smart grid systems to enable the interoperability between various vendors of equipment. In our final edition of our series on Automation, we will cover the role and applicability of the famous IEC 61850 protocol in automation for distribution network.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →