Technical Article

Published 07/2019

Exploring Distribution Network Automation Options

Elementary Automation without Communications

Automation of the electricity distribution grid provides substantial economic benefits for utilities and society. Effective fault location and network restoration can in most cases be converted to an algorithm, enabling the optimisation of network reliability and providing resilience to network faults. The techniques for achieving distribution network automation are varied, and whilst the merits of automation can be lauded as “network modernisation”, carefully considered automation can create genuine returns for utilities.

In the electricity distribution context, Distribution System Automation (DSA) can be summarised as the automation of reclosing (of circuit breakers) and switching (of load break switches or isolators), with the goal of restoring power to the largest number of customers in the smallest, safest time interval.

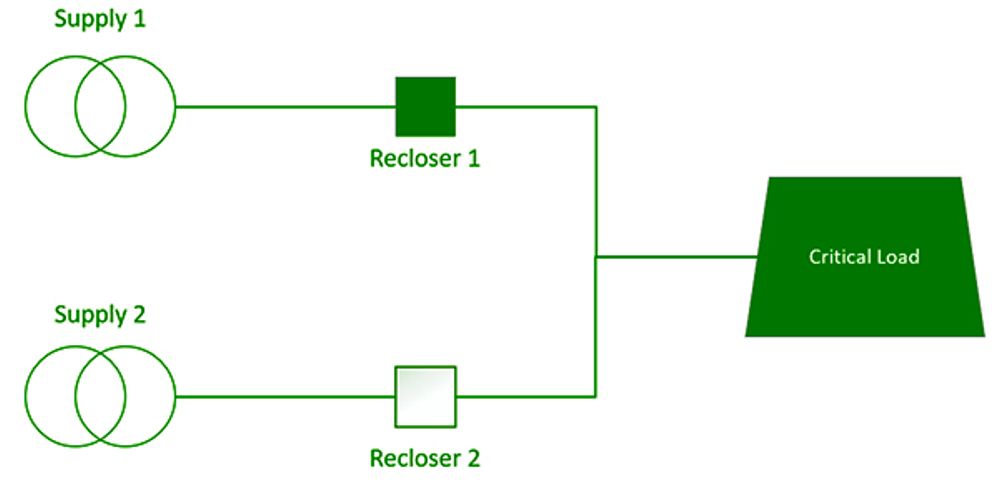

This article is the first of a series, covering the many Distribution Network Automation techniques available to Power Systems engineers. The most elementary case is of an Auto-Changeover Scheme without peer to peer communications. Today, we explore the techniques and evaluate their costs, benefits and limitations of the simple Auto Changeover Scheme achieved with Reclosers and no communications necessary.

This case uses voltage sensing on both the Supply and Load side of the Autorecloser, which is available as standard on the NOJA Power OSM Recloser system.

Logically, the intent is to maintain uptime of power availability for the critical load. Therefore, Recloser 1, the main supply, stays closed. In this state, recloser 2 will be normally open (NO), and will see voltage on both sides of the open circuit breaker.

If supply 1 fails, Recloser 1 can detect this condition and open. Recloser 2 also notes the loss of supply and commences a countdown timer before closing in Supply 2.

To prevent back-feeding into Supply 1, the only criteria necessary is for the opening recloser to be faster than the closing one. In this case, Recloser 1 should trip on undervoltage before Recloser 2 closes to restore power.

NOJA Power’s OSM Reclosers can be configured to re-arm their Voltage restoration closing function if they opened due to loss of supply, such as the Recloser 1 case mentioned above.

Benefits

Primary benefits of this system are simplicity and cost – there are no communications systems necessary to implement the automation, and only two reclosers to control the switching.

The term “Critical Load” is also quite broad, not only could the load be a single building such as a hospital, but this method has been applied for supply to entire suburbs or towns, where two supply feeders at either ends of the town work in tandem by sensing the voltage presence and switching supply on the failure of the main supply.

Drawbacks

The core issue is if there is a fault between the circuit breakers and the load, the restoration system will cause an additional close onto the fault, and hence a reenergisation of the fault site.

This is a common theme for automation schemes that do not have communications, but if this additional single reclose is tolerable for the scenario then the simple automation system can be highly effective in improving network reliability.

Another possible challenge is the training of operations personnel to understand that opening one circuit breaker, particularly for line work, can cause another breaker to close and energise the circuit. In our experience, this is handled well through signage and interlocks at the controller site. Another option is to have centralised communications to both devices, allowing remote operators to disable the automation before work commences, but this adds complexity and cost, which we will consider in our next article instalment.

“Reclosers are the key building blocks for smart grids. Customers investing in the deployment of reclosers on their network will improve reliability,” says NOJA Power Group Managing Director Neil O’Sullivan. “Adding automation based on logic built into the devices, automation based on centralised communication or automation based on peer to peer communication is all possible step by step once the recloser building blocks have been deployed.”

Join us next week as we explore the next automation network topology in our series.

Want to stay up to date with Electrical Distribution Technology?

Join our list for a free weekly technical bulletin, as we share our Global Electrical Engineering experience directly to your inbox.

Subscribe →